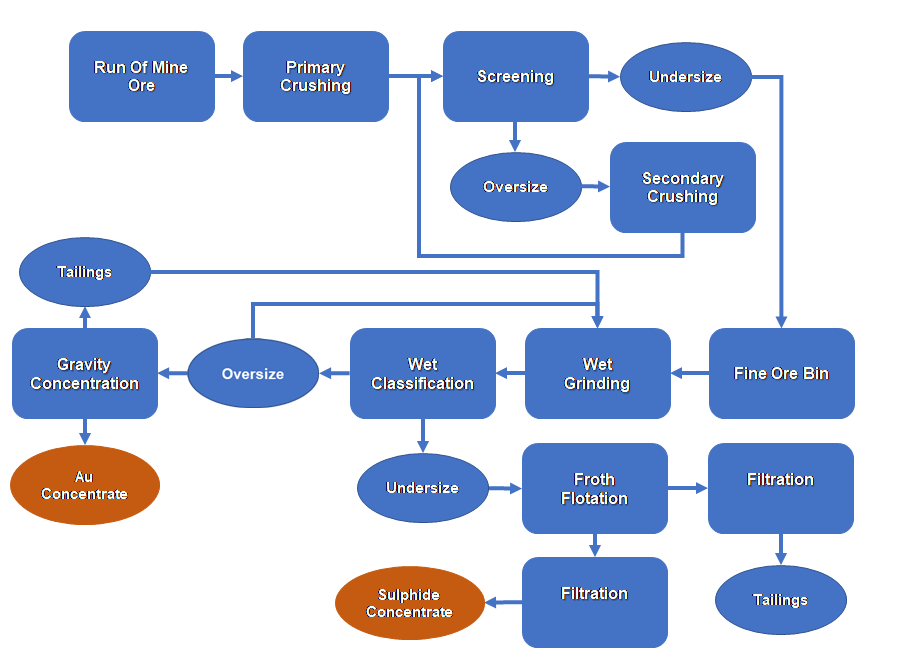

The Cononish processing plant will be constructed in two Phases – Phase 1 will provide a throughput of 36,000 tpa of ore and will consist of crushing, grinding, gravity concentration; froth flotation and dewatering sections. Phase 2 will provide a throughput of 72,000 tpa and will involve expansion of the grinding, gravity concentration and froth flotation sections. The crushing section will already be capable of the Phase 2 throughput of 72,000 tpa from commissioning.

ROM ore will be crushed from 250mm in diameter in the primary jaw crusher and the crusher product screened at 20mm. Screen oversize will be crushed in the secondary jaw crushers and returned to the screen. Screen undersize will be conveyed to the fine ore bin. The fine ore bin will feed a 2m x 3m wet ball mill operating in closed circuit with a hydrocyclone. The hydrocyclone underflow will be split and part returned to the ball mill with the remainder passing to the gravity concentration circuit consisting of a Knelson centrifugal separator and a conventional shaking table. The gravity concentrate will be smelted directly to produce gold doré. Tailings from the gravity concentration circuit will be returned to the ball mill.

The hydrocyclone overflow will pass directly to froth flotation, consisting of rougher, scavenger and cleaner stages. Flotation will be bulk sulphide flotation and the cleaner concentrate will be dewatered in a pressure filter and sent off site for further treatment. The flotation tailings will be dewatered in a pressure filter and the tailings sent to the Tailings Management Facility (TMF) for dry stacking to emulate the natural glacial features of the area.

Overall design target recoveries are 93% Au and 90% Ag with approximately 25% of the Au and 5% of the Ag reporting to the gravity concentrate and the remainder to the flotation concentrate.