Annual / Half-Year Reports

Quarterly Reports

JORC CODE COMPLIANT RESOURCE REPORT

Cononish Farm Gold Mine Planning Application

Prospectus Scotgold September 2010

Scoping Letter

Gordon Watson

Director of Planning

Loch Lomond and the Trossachs National Park Authority

Carrochan

Carrochan Road

Balloch

G83 8EG

| 21 August 2009 Our Ref: KVD/CON/01[R] |

Dear Mr Watson

Scotgold Resources Ltd

Cononish Farm

Proposed Gold Mine with associated service and production buildings, plant, tailings storage area, pond and gauging station, access roads and bridges and diversion of burn [Revised proposal - Ref 90/01102/DET/S]

Environmental Impact Assessment [Scotland] Regulations 1999

Scoping Request

As you are aware from our meetings and correspondence Dalgleish Associates Ltd is currently preparing, on behalf of Scotgold Resources Ltd, an Environmental Statement to accompany the forthcoming application, as detailed above. The application is for a revision of the extraction and processing operations which were permitted in 1996 under the above reference, followed by final restoration of the site and is for a 10 year period.

The site has been on a care and maintenance regime only, under the previous operator, Fynegold Ltd and since spring 2007 under the current lessee, Scotgold Resources Ltd. Scotgold Resources has also undertaken in that time a programme of site rehabilition, namely the removal of derelict portable site offices and redundant structures and making wind and watertight the main workshop/core storage facility. It also set out to the Parks Authority a programme of environmental baseline and feasibility studies with respect to an improved mine design and ore process to modern standards.

The applicant, Scotgold Resources Limited [SC309535] is a wholly owned subsidiary of Scotgold Resources Limited [Australia], with registered offices at Upper Tyndrum Station, Tyndrum and is a mineral development and exploration company with mineral interests [substantially through three granted Crown Licenses amounting to some 2200km2] in central western Scotland. Scotgold Resources Limited (Australia) is a publically listed company on the Australian Securities Exchange (ASX)

As the application site extends to greater than 25 hectares, Scotgold Resources Ltd considers that the proposal falls under Schedule 1 of the Environmental Impact Assessment [Scotland] Regulations 1999, as amended, and Environmental Impact Assessment [EIA] is mandatory.

The applicant is also conscious that the River Tay SAC, which includes the River Cononish, has been designated since the grant of the original planning permission in 1996 and that the Water Environment and Water Services [Scotland] Act 2003, which inter alia provides for protection of groundwater per se, has been implemented through the Water Environment [Controlled Activities][Scotland] Regulations 2005. The Nature Conservation [Scotland] Act 2004 places further onus on the applicant with respect to potential impacts on wildlife as does the Conservation [Natural Habitats & c] Regulations 1994, as amended 2007.

Accordingly, under Paragraph 10 of the Regulations, we request a scoping opinion as to the content of the Environmental Statement. To assist you in your response we have supplied plans identifying the site area, the location of the proposed site infrastructure, the development stages of the Tailings Management Facility and the proposed final restoration.

The location of the flow gauging station on the River Cononish is also shown.

Accompanying the plans is a description of the components of the development and the identified key issues which we would propose to address.

History and Overview

An extensive stream sediment sampling program was carried out across Scotland by the British Geological Survey in the late 1960s and early 1970s and the Dalradian sequence was identified as highly prospective for both gold and base metals. The high incidence of gold in these samples attracted various exploration companies to the region and Ennex International plc through its Scottish subsidiary, Fynegold Exploration, commenced prospecting in 1984.

In 1985, the program identified a promising structure at Cononish which was investigated by initial trenching and subsequent diamond drilling. A further phase of diamond drilling in 1987 began to delineate a substantial resource. Further drilling was conducted in 1988 and in 1989, planning permission was obtained to drive an underground adit to examine the grade and continuity of the structure. 1110 metres of level development and 173 metres of vertical development were completed and the results justified the preparation of a feasibility study as a prelude to an application for planning permission to develop Scotland's first modern underground gold mine. The application was submitted in 1991 and subsequently granted in 1996.

During this period, ownership of the project [through Fynegold Exploration] had passed to Caledonia Mining Corporation whose intention it was to put the mine into production in 1997.

In 2000 the project was put on care and maintenance as a result of a sharp decrease in the availability of funding for junior mining companies combined with a sustained cyclical low in the gold price. The Oak Consortium acquired Fynegold Exploration from Caledonia in 2001 and Fynegold Exploration was purchased by Scotgold Resources in May 2007.

Site Location and Description

The current permission area comprises some 36.5ha with a separate, small area of 0.2ha some 600m to the east containing the water quality monitoring station.

Figure 1 - Click to enlarge |

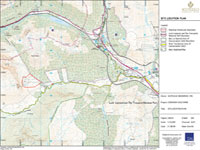

Figure 338/01 shows the site in relation to the nearest settlement, Tyndrum and identified designated areas and routes. The site area is centred at Grid reference NN 2950 2865.

The mine complex occupies the lower slopes at the head of the main valley of the River Cononish, at its junction with the Allt Eas Anie. To the immediate west of the mine entrance the ground rises steeply to the southern end of Coire na Saobhaidhe. Surface drainage from Beinn Chuirn, to the north west of the corrie, flows in part over the Eas Anie waterfall some 200m to the south west of the mine entrance.

Currently the site elements comprise:

- gated access track from Cononish Farm

- the mine adit entrance

- the mine fill plateau [material from the exploratory adit]

- diamond drilling core storage and equipment/plant storage sheds/container

- surface water cut-off ditches

- three settlement lagoons

- water monitoring facilities

Figure 2 - Click to enlarge |

The former core storage and office compound has been cleared and levelled and core rehoused at the mine plateau. Peat storage bunds associated with the original development works may be seen below the mine plateau adjacent to the track.

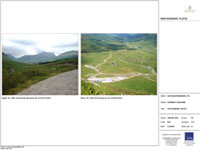

Figure 338/02 shows the site from the east and from the hillside above the mine entrance looking down the Cononish valley to Cononish Farm.

Proposed Operations

Scotgold Resources Ltd, in acquiring the land and mineral leases for the Cononish development in May 2007, wish to complete the development permitted in 1996 and thereafter implemented.

Scotgold has undertaken a review of the mining data and completed a scoping study. The Company has also reviewed and updated the gold extraction process to be employed, together with the necessary mine tailings management facility.

The Cononish proposals involve the establishment of a small underground mine accessed by a horizontal entry tunnel. Broken rock from the underground operations is transported to surface where it is processed to remove the valuable mineral constituents, primarily gold and silver with ancillary lead, copper and zinc.

Processing consists of crushing and grinding the material to a fine 'powder' in slurry form subsequent to which a 'gravity concentration process' removes approximately 25% of the gold and silver, which will be smelted on site to form an impure gold bar.

The residues from this process are further treated by 'froth flotation' to remove the remaining gold and silver into a 'sulphide rich' concentrate [also containing the lead, copper and zinc] which will be transported off site for further processing to release the gold and silver.

Reserves

The gold and silver mineralisation at Cononish occurs within a northeast - southwest trending quartz sulphide vein hosted by the psammites and pelites of the Lower and Middle Dalradian stratigraphic sequences, prevalent in the south western Grampians.

The quartz vein varies in thickness between a few centimetres and eight metres wide with an average width of just under two metres and dips between 60o to 90o degrees from horizontal. The area currently identified for mining has a strike length of some 600 metres and a dip extent of 300 metres.

Current estimates suggest a mineable inventory of around 450,000 tonnes of ore and recent drilling and interpretive work indicate that there is a strong likelihood that this inventory will increase. At currently proposed production rates of 72,000 tonnes of ore per annum, this inventory is sufficient for six and a half years operation [exclusive of a construction period of around twelve months].

The location and aspect of the current inventory, within the southern flanks of Beinn Chuirn, allows the mine to be developed from a horizontal tunnel rather than by shaft. The existing adit will be widened and an internal network of connecting tunnels developed to connect the working levels of the mine for extraction operations. A mining method called 'sub level open stoping' is proposed as the main source of production, this is a highly productive safe 'non entry' [ie limited access to the working areas] method practised world wide.

Method of Working - Mining Operations

The mining operation essentially consists of four main processes, drilling, blasting, loading and hauling.

The first part of the process is the drilling of small [50mm] diameter holes in the rock to be mined for charging with explosives. Drilling is generally carried out by electro hydraulic and / or compressed air drill rigs mounted on a diesel powered carrier.

Blasting is used to break in situ rock into a size suitable for handling and processing and consists of loading the drilled holes with commercial explosives. A number of these holes are then 'fired' sequentially at the end of a shift to break rock for loading and hauling to the processing plant on the following shift.

Broken rock is loaded by 'load - haul - dump' [LHD] diesel powered vehicles - similar to a front end loader but adapted for underground use - and tipped into 11 ton underground diesel trucks. These transport the rock from underground to the crushing plant reception bin.

Processing

The crushing plant is located within the process buildings. Broken rock from underground is dumped onto a 250mm fixed bar grizzley screen with larger rock being retained on the screen for secondary breaking. Rock less than 250mm passes through the grizzley to the primary crusher. Primary crusher product is screened at 12mm with oversize undergoing a further phase of crushing to reduce the size of feed to the mill to a nominal -12mm. An ore storage bin is provided ahead of the grinding mills to ensure a constant flow of material to the milling process.

Ore is 'wet' ground in a 'ball mill' to the fineness required by the following gold separation processes.

Gravity concentration relies on the very high specific gravity of gold and a series of physical processes separates high specific gravity material from waste material. The concentrate from this process is held in a storage bin until sufficient has been produced to warrant further cleaning to a product suitable for smelting. This gravity concentrate is mixed with fluxing material [to remove impurities] prior to smelting in a small crucible furnace from which a small bar containing 80% gold, 10% silver, is poured.

Gold particles in the Cononish ore are relatively fine, with 90% less than 100 microns in size and gravity processes will only recover about 30% of the contained gold. A further process, froth flotation, is required to recover the balance of the gold.

The flotation process recovers fine gold particles associated with gold locked up with the sulphide minerals of iron, copper, lead and zinc contained in the Cononish ore. It is a commonly used process for the recovery of many minerals, in particular sulphide minerals.

A slurry of finely ground particles and water is passed through a number of 'flotation cells'. The slurry has a flotation and a frothing agent added and is aerated and agitated as it passes through. A 'mineralised' froth containing sulphide and gold particles rises to the surface of the cell which is collected as the flotation concentrate. The material that does not float is comprised of unmineralized particles, known as tailings, which require to be disposed of in the 'tailings' management facility.

It should be noted that no cyanide or mercury is used in these processes with the likely flotation reagents being sodium isopropyl xanthate and methyl isobutyl carbinol. These chemicals are used at a rate of around 150 grams per ton of material processed.

The flotation concentrate is dewatered to about 8% moisture using a filter prior to being discharged into 1.5 ton bags for transportation off site.

72,000 tonnes of ore will be mined and processed annually to recover 20,000 ozs and 80,000 ozs of gold and silver respectively.

Tailings Management Facility

Approximately 4% of the original ore will be recovered as concentrate with the balance to be disposed of as tailings. Tailings are pumped from the processing plant by pipeline to be stored in a tailings area situated immediately below the plant site. Tailings are impounded behind an engineered embankment.

As part of the construction phase, an initial embankment 12 metres high, sufficient to store one years production, will be constructed from till material with a rockfill toe prior to the commencement of production. Peat will be stripped from the main embankment footprint and from within the tailings basin and temporarily stored. Peat turves will be used in landscaping of the embankment face.

Once the peat has been removed, the borrow area for embankment construction will be developed in the underlying glacial till leaving at least one metre of till over the bedrock to provide a natural low permeability liner to minimise seepage from within the tailings storage area.

Subsequent embankment lifts will be constructed annually from till material, tailings solids and waste rock and each lift will be landscaped using peat turves.

During operations the tailings slurry, which contains about 25% solids by weight will be discharged from the tailings line along the tailings 'beach' on the upstream side of the embankment. Coarse particles settle out quickly propagating the tailings beach with finer particles settling further into the tailings pond.

The tailings facility is designed to be capable of being expanded to store 1,000,000 tons of tailings should additional resources be located.

The tailings facility receives water from three sources: the process plant tailings, drainage from the underground mine and precipitation over the catchment area of the minesite and tailings facility. A return water system via a submersible pump and pipeline is provided to enable water to be recycled from the tailings pond for use in the plant.

A smaller compacted earthfill embankment is located downstream of the main facility to form a 'recirculation pond' whose function is to control any discharges of supernatant water from the tailings area. The pond also serves as an emergency pollution control dam to cater for any inadvertent spillages of tailings and runoff water from the main tailings and site areas. Interceptor ditches, which discharge into the recirculation pond, are provided to catch any such events. Water may also be pumped from the recirculation pond for re-use in the plant.

Surplus water from the site will be discharged to the Cononish River in accordance with the licence issued by the Scottish Environment Protection Agency. Discharge is through a an automatic discharge valve system linked to a data logger in the Cononish River to ensure correct dilution levels.

In order to accommodate the tailings facility, the Eas Anie Stream requires to be re-routed outside the tailings basin. A diversion channel capable of handling a 1 in 10,000 year flood will be excavated in rock and overlying glacial till.

Figure 3 - Click to enlarge |

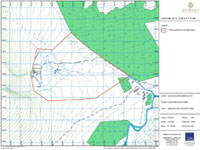

Figure 338/03 shows the site boundary and the location of the proposed site infrastructure, much of which will occupy a levelled area below existing ground surface and will be further substantially screened by landscaped mounds. All buildings will be acoustically clad with exterior corrugated sheeting in a recessive green/brown shade. Landscaping of the features has been revised and some changes to the former planting regime are proposed.

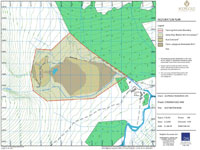

Figure 338/04a shows the site layout plan with the pre-deposition tailings embankment and borrow area and Figure 338/04b and 338/04c show the extent of the 600,000 tonne and 1,000,000 tonne tailings management facilities respectively. The re-circulation pond is some 6m high at the crest; the pre-deposition embankment 12m. At its crest the 600,000 tonne facility embankment will be around 26m in height, an additional 10m being necessary to contain a further 400,000 tonnes of tailings.

Figure 4a - Click to enlarge |

Figure 4b - Click to enlarge |

Figure 4c - Click to enlarge |

Restoration

A programme of rolling restoration will be implemented in tandem with the site construction works. A landscaped screening mound will be constructed around the process plant building using materials excavated for the footprint of the building and accesses. Peat turves will be set aside and placed on the slopes of the screening mound following its reconstruction. A similar process has been described above for the tailings management facility and recirculation pond embankments. Once established the turves will knit together to provide a natural revegation cover.

Figure 5 - Click to enlarge |

Establishment of native species will be undertaken as indicated on Figure 338/05. Scotgold Resources Ltd will liaise closely with Loch Lomond and The Trossachs National Park Authority on the principle and detail of the restoration to ensure that the proposals are commensurate with identified landscape objectives.

Glacial till from the excavations together with rock excavated from the development of the mine will be used to regrade the east face of the mine fill plateau, prior to the placement of peat turves in conjunction with seeding with a locally derived acid grassland seed mix, reflecting the plant communities in the immediate environs. The valleys, lower slopes and ridges with a shallow gradient carry blanket peat and its range of associated plant communities, grading from very waterlogged areas with restricted drainage to drier areas at the limit of peat forming capability with better drained slopes supporting a variety of acid grassland plant communities.

On cessation of mining operations the mine will be de-commissioned and all process plant removed from the site. Built infrastructure will be dismantled and the footprint of the plant area and other site facilities routed, graded, available soil forming materials spread and seeded.

A small facility can be retained to provide for a visitor experience post closure.

The surface of the tailings area will also provide an environment suitable for the establishment of valley bottom blanket mire communities by seeding of locally derived species. There are several successful techniques to achieve this, including strewing a mown cut from neighbouring land. A programme will be implemented to monitor the progress of the restoration.

Aftercare

Following restoration the site will be managed for an aftercare period of 5 years, in accordance with the Town and Country Planning [Scotland] Act 1997.

Environmental Impact Assessment

In the period 1989 - 1990 extensive environmental baseline studies were undertaken as part of the planning application process for the 1996 permission. These studies have been reviewed and updated over the past 24 months. There now exists a body of environmental information which provides for a comparison of natural changes which may have taken place in and around the site in this 20 year period and against which any potential impacts may now be re-assessed.

Key Issues

Following a re-appraisal of these potential impacts, in light of mine and process design modifications and matters and concerns raised by consultations to date, the key issues have been identified as:

- the hydrological and hydrogeological impact of the development

- the ecological impact of the development, in particular on the nearby River Tay SAC

- the landscape and visual impact of the development

- socio-economic impacts of the development

Minor Issues

With lesser potential for impact minor issues are considered to be:

- operational noise from earth moving machinery and process plant

- dust arising from site operations and in dry windy conditions dust emissions from the surface of the tailings disposal area

- vehicle movements on the access track and possible conflict with recreational users

- the archaeological interest of the site area

Potential Benefits

The aims and objectives of the Loch Lomond and Trossachs National Park include a fostering of the understanding of the natural environment. Scotgold Resources Ltd is committed to providing a visitor facility in Tyndrum focussing on the geology and mining history of the area and the discovery of gold with the further potential for an on-site mine tour.

The mine will provide employment for around 50 - 60 people, the majority of whom will be sourced from the local area, with the exception of around 13 specialist positions.

Scottish gold may attract a premium, as does Welsh gold. Scotgold would be supportive of a goldsmith/silversmith enterprise in Tyndrum.

These issues will be addressed within the ES and, to assist in this scoping response, are discussed briefly below.

Landscape and Visual

Changes in the approach to the assessment of landscape and visual impacts have been made since the original submission in 1990. Consequently the ES will contain a landscape and visual assessment carried out utilising the methodology and approaches as recommended by Guidelines for Landscape and Visual Impact Assessment prepared by the Landscape Institute and Institute of Environmental Assessment 2nd ed. [2002] and Landscape Character Assessment Guidelines for England and Scotland [2002]. Appropriate consideration will be given to the Loch Lomond and the Trossachs Landscape Character Assessment prepared by Environmental Resources Management in 2005 [SNH Commissioned Report No.093] and to An Evaluation of the Special Qualities of Loch Lomond and The Trossachs National Park, Technical Appendix to the National Park Plan 2007 - 2012.

The landscape impact assessment will identify and assess the existing impacts and the likely impacts which the proposal will have on the landscape, both during operations and post restoration, and will consider mitigation where appropriate.

The visual envelope of the development will be identified and a visual assessment undertaken at selected viewpoints that are considered as being representative of the surrounding area. Viewpoints will be agreed in advance with Scottish Natural Heritage.

Hydrology and Hydrogeology

An assessment of hydrology and hydrogeology will be undertaken. The assessment will consider all potential pollution impacts from the proposal and provide appropriate mitigation where necessary. Scotgold Resources Ltd is cognisant of the proximity of the Cononish River and its status as an SAC. The Company has continued to liaise closely with the Scottish Environment Protection Agency [SEPA] in respect of its pollution prevention and mitigation measures.

The proposed site water management schemes will be subject to assessment and modification as required to ensure that site water is managed appropriately in accordance with the Groundwater Regulations 1998, the PPC Regulations 2000, the Water Environment and Water Services Act 2003 and the Water Environment [Controlled Activities][Scotland] Regulations 2005 and its 2007 amendment..

Any oil, fuel, lubricant or other potential pollutant will be handled on the site in accordance with SEPA guidelines to ensure prevention of pollution of any watercourse or aquifer.

The Mining Waste Directive is to be implemented in Scotland through the planning regime and legislation is expected in the autumn of 2009. The equivalent category in the Environment Agency Permitting regime for the proposed tailings management facility is a Category A site. The design of the facility has been reviewed in view of this directive and the requirement to consider seismic events.

Ecology

The ES will address the current situation and the impacts of the proposed development, detailing appropriate mitigation where necessary, and will consider the long-term residual impacts following reinstatement of the land. The site has been subject to a Phase 1 habitat survey, ornithological surveys, and mammal surveys, as necessary, to provide baseline data for impact assessment.

Noise

A statement will be prepared on noise emitting from site operations with respect to potential sensitive receptors. It is proposed that the operations will be designed to accord with the recommended criteria set out in Planning Advice Note, PAN 50, Annex A "The Control of Noise at Surface Mineral Workings".

Dust

The ES will address both nuisance and respirable dust. An assessment of potential dust generating sources will be undertaken to determine the best methods of limiting or suppressing dust from the proposed operations. A Site Dust Management Strategy will be prepared following Planning Advice Note, PAN 50, Annex B "The Control of Dust at Surface Mineral Workings", which is considered to be relevant guidance. An assessment of the potential impact on sensitive receptors will be undertaken.

Blast Vibration

An assessment of blast vibration will be undertaken with respect to any potential sensitive receptors.

Traffic

In the construction phase plant will be brought to the site via the railway crossing track at Tyndrum Lower Station, joining the track in the Cononish valley at a point some 2km east of the mine site. A 12 month construction phase, which includes underground development works, is anticipated.

Thereafter vehicle movements will relate solely to site staff and fuel deliveries. A shuttle transport will take staff to the mine site from a dedicated car parking area, potentially located at Dalrigh. Gold bearing concentrate will be transported from the site in 1.5 tonne bulk bags by a small [5t] commenrcial vehicle to a suitable container loading site and shipped in 28t containers either by road or road/rail. Concentrate productions are estimated at 45t per week and would represent 9 commercial vehicle movements from the site weekly.

Archaeology

An archaeological desk based and walk-over re-assessment has been undertaken to update site information. The ES will consider the archaeological baseline of the area, the potential effects of the proposed development, both in terms of physical impact and impact on setting, and where relevant the mitigation necessary for management of the archaeological resource.

Rights of Way

The ES will address the potential impact on rights of way, footpaths and general area access. Consideration will be given to the potential for increased recreational access within the restoration proposals.

Content of the Environmental Statement

It is proposed that the issues identified above will be addressed in detail within the Environmental Statement. The ES will also give consideration to other matters such as Planning Policy, Need, Cumulative Impact and the Consideration of Alternatives. The ES will also contain a pre-application consultation [PAC] report demonstrating compliance with the requirements of the Town and Country Planning [Development Management Procedure][Scotland] Regulations 2008.

We look forward to your confirmation that the proposals detailed above are adequate or alternatively that there are other issues which require consideration.

Yours sincerely

Karen Dalgleish

For Dalgleish Associates Ltd